Because of the portability of the equipment and variety of methods available, ultrasonic testing allows for inspection of parts that are large, irregularly shaped, or unable to be transported.

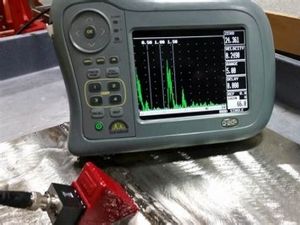

Ultrasonic inspection relies on electronic transducers that transmit high-frequency sound waves to a material. These sound waves bounce back crystal-clear images, which reveal key characteristics about a material’s properties. The images created by ultrasonic testing can indicate cracks, weld grooves and fractures, as well as indicate material thickness and outline moving components.

Because this method has higher power potential than other non-destructive test types, ultrasonic inspection can produce images that are more clearly defined than other methods, and indicate characteristics deeper than surface level. Depending upon the test requirements, parts can be tested by immersion (in-lab testing) or contact (portable/in-air) inspection.